Some notes concerning LEDs as safelights .....

Last update: 2017/1/21

LEDs are now a low cost option for making high quality and efficient darkroom

safelights. However their performance is dependent on the selection of the

correct types otherwise there is the risk of fogging.

Not all red leds are the same and the selection of red / orange types is

critical.

Pure red LED's for orthochromatic (and multigrade) papers should be the super

high efficiency or hyper red types with GaAlAs semiconductors. These have a low

spectral bandwidth that does not extend below 600nm. Incorrect (and cheaper)

LED's extend down to 550nm which will easily fog ortho papers. Another

suggestion is to have red not clear packaging.

There is a family of far red LED's which appear to cut off completely at 650nm

and peak at 730 - 750nm. These are interesting for use as ultra safe ortho film

safelights and also there is the possibility that they may be safe with normal

panchromatic film.

This will be tested at the earliest opportunity.

LED's for Multigrade Papers are more difficult to source and should preferably

be of the Red/Orange or amber types, not orange. The selection of suitable

types is therefore limited, at the moment, to the Luxeon Rebel LXML-PH01-0050

red/orange 617nm high power led and the amber Osram LA G5AP which has now been

tested and shown to be similar to the Luxeon. Both are surface mount so

soldering is required.

The links below is benchmark data concerning the performance of existing

safelight filters.

1.

Ilford Safelights:- types 902 / 904 Orange for multigrade

etc, type 906 for orthochromatic papers

2.

Kodak Safelights Wratten 1A Light Red for orthochromatic

and multigrade etc.

Below is a selection of data sheets for super high efficiency leds.

1.

5mm diameter red Kingbright L-7113SRD

0.08 lumens at 20mA, 60 degree angle, with leads

2.

8mm red diameter Kingbright L-793SRD-E

0.34 lumens at 20mA, 60 degree angle, with leads

3.

10mm diameter red Kingbright L-813SRD-E

0.42 lumens at 20mA, 60 degree angle, with leads

4.

Luxeon Rebel LXML-PD01-0030 high power leds, red and

red/orange

2.9 lumens at 20mA, 120 degree angle, surface mount, ceramic substrate

5.

Osram LS

T676-Q2. Low power surface mount super red.

0.3 lumen at 20mA, 120 degree angle, surface mount

6.

Osram LA T676-Q2. Low power surface mount amber, probably

suitable.

0.3 lumen at 20mA, 120 degree angle, surface mount

7.

Osram G5AP-CXDX-24-1.

This is a preferred red/orange led. 2.9 lumen at 20mA, 120 degree angle, medium

power, surface mount, easier to solder than the Luxeon Rebel and has now been

shown to be suitable. However see the Prolite range below.

8.

The Prolite Range of 1W LED's with normal leads

These are much bigger than the typical surface mount types and are easily hand

soldered.

The red can be used for normal paper.

The cherry red is a far red type which can be used for ortho paper or perhaps

normal film.

The use with normal film has still to be tested but their specification looks

promising.

This is now the preferred range for all applications.

9.

Here is a super high efficiency led that is not suitable.

Typical applications are as follows:

I use a low cost commercial 13.8v/2 amp regulated supply as power source. This

is distributed around the darkroom for a variety of uses.

1. Illuminating a traditional darkroom clock:

Use 1 or 2, 5mm red leds, L-7113SRD, with 3mA current.

2. Providing local safe lighting below an enlarger:

Use 1 Luxeon Rebel red/orange or red (50lm/W)with 3mA current. If the light is

attached to the enlarger head the current can be switched to 1.5 or 6mA

depending on the distance of the light from the easel.

Typical light level is 1 to 2 lux using a normal luxmeter.

3. Main safelight above processing trays: Use 2 Luxeon Rebels (50lm/W) with

10mA current, spaced 0.7m above the trays and 1m apart.

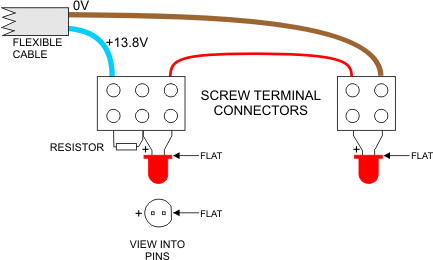

Here is a schematic relating to the 3 examples above and a

suggested implementation for examples 1 and 3 is given at the end of the page.

TESTING:

This section was modified on 2015/11/20. The use of a darker grey is more

effective at revealing safelight fogging.

Find the print time required to give a significant grey (reflection density 0.3

- 0.4) on the processed paper, which looks about half as dark as an 18% grey

card. Expose further test samples in the same way and use these to check for

fogging in various areas of the darkroom.

A typical procedure would be to place a coin in the centre of a pre-exposed

square test sample and expose each corner differently to give 4, 8, 12 and 16

minute exposure to the safelights.

Process and when dry, compare each corner to the centre reference and other

corners.

With the above new test, and Ilford Multigrade IV filtered to grade 2, the

above red/orange led safe lights, at a distance of 750mm, should allow greater

than 8 minutes exposure before fogging is noticed.

A similar test carried out with an Ilford safelight and 902 filter, at the same

light intensity level, gave very similar results to the red/orange leds.

Suggested implementation with no soldering.